Artículos técnico

Publicado 12/2023

Terminals 101 – Understanding Connectors for MV Switchgear

As with most engineering decisions, the methods for physically connecting overhead electricity distribution equipment are a trade-off between cost, reliability, and ease of connection. Electrical engineers have developed many methods for connecting the equipment over the years, each with their own merits and disadvantages.

In this article, we cover our two most common types, and elucidate the up and downsides that each option delivers.

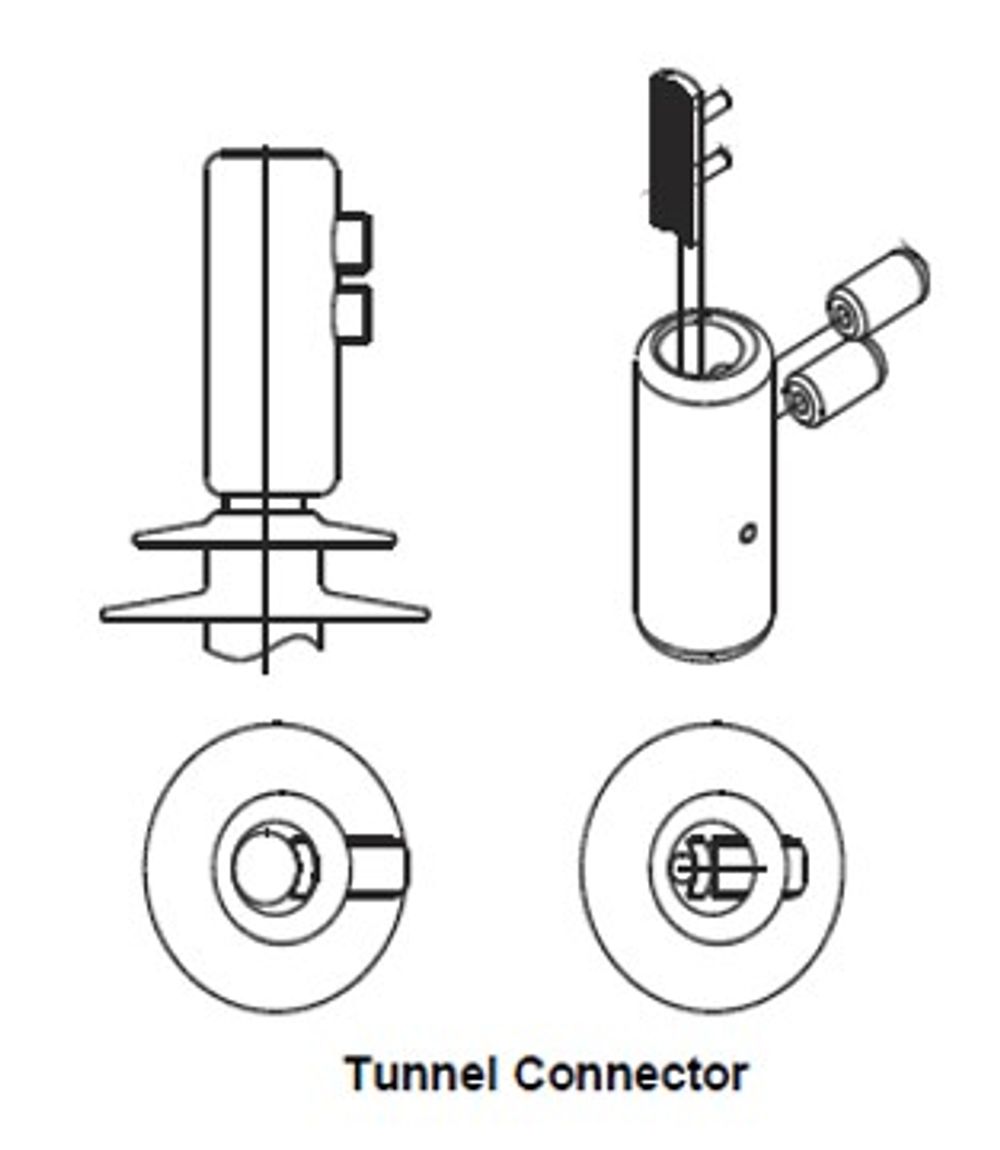

Option 1 – The Tunnel Connector

Far and away the most common connector that NOJA Power delivers with the OSM Recloser System, the Tunnel Connector is the choice for versatility.

The tunnel connector assembly is a tin-plated brass cylinder with an internal pressure plate. The cylinder entry accepts any cable size from 44 mm2 to 260 mm2.

When connecting overhead lines to the device in the field, linework teams simply need to strip the conductor, insert the bare conductor into the connector, and tighten the Allen Keys to 30 Nm to lock the cable in place.

Advantages:

- Cost

- Versatility

- Simplicity

The Tunnel connector uses the least material (on the switchgear side) of any connector types, and therefore is the lowest cost option for the connection. It can also be used across a wide variety of cables, meaning the standard product will be compatible with the greatest number of overhead distribution connection applications. And lastly, the connection is as simply as clamping two allen keys on an inserted line. Simple.

Disadvantages:

- Durability over Time

- Transport

The biggest problem with tunnel connectors is ensuring the torque of the Allen Key bolts are maintained. The torque ensures that an adequate low impedance connection to the switchgear is made, so that hotspots don’t form on terminals.

If the Recloser is supplied “pre dressed” – that is, with all cable tails and surge arrestors fitted before installation (or arrival to site), then there’s a risk they will shake loose, or the cable itself will deform in the terminal during transport and need re-tightening.

This shortcoming means that most users who opt for “pre-dressing” of switchgear go with option 2 on our list. And that is, the Palm Connector.

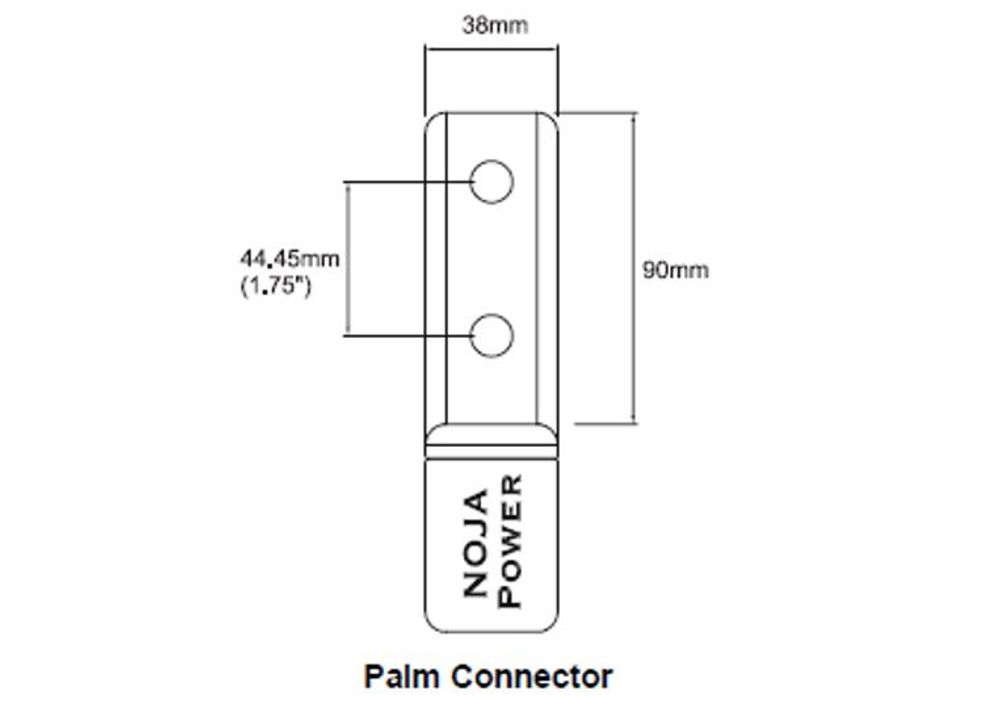

Option 2 – Palm Connector

Also known as NEMA Palms, these connectors are spade designs which have provisions for multiple bolts to connect pre-terminated overhead cables to the lines.

This design relies on a NEMA style “lug” being attached to the overhead line, before the final connection is made bolting the overhead lug to the switchgear palm. For the NOJA Power VISI-SWITCH® and OSM Recloser, the palm connectors accept an M12 bolt, which should be tightened to 50 Nm.

There are various permutations of the Palm available, such as four hole, threaded and non-threaded, but for this article we’ll consider the basic unthreaded 2 hole palm connector.

Advantages:

- Connection Reliability

- Easy surge arrestor tail connections

The primary reason for opting for Palms, (unless your local standards mandate their use), is for connection reliability. The use of multiple M12 bolts and the inability for cables to warp in the termination makes this connection type the most secure. Engineers are far less likely to encounter hot spots on palm connector terminations.

The added advantage of a bolted palm design is the simplicity of connecting surge arrestor tails. Surge arrestor tails can be fitted with their own spade lugs, and grouped by a bolt connecting the overhead line to the switchgear. Conversely, with the Tunnel connector, surge arrestors must be connected using parallel groove clamps, requiring far more bolts to be tightened, and introducing risk of cable deformation.

Disadvantages:

- Cost

- Complexity

Firstly, Palm connectors have more material than a tunnel connector, and therefore cost more. The other added cost is the requirement for a line-side lug, which itself is a substantial piece of metalwork. On average, a palm connection is more than twice the cost of a tunnel connector. This should be weighed against the cost of maintenance and reliability.

The palm is also slightly more difficult to assembly than a tunnel connector. Tunnel’s can be inserted and clamped, all done, whereas Palm connectors require a technician to clamp or affix the lug to the overhead line, before bolting the lug to the Palm connector. It’s an additional step, making it a bit more complex than the alternative.

Conclusion

“Our recloser products have evolved over the years to meet customer requirements,” says NOJA Power Group Managing Director Neil O'Sullivan.

“This includes various termination arrangements together with bird guards to suit those termination arrangements for customers to achieve a fully insulated bushing arrangement to provide maximum reliability."

NOJA Power provides both Tunnel and Palm connector options for their range of switchgear. These designs both have their merits, and the optimum choice varies on application. For more information on switchgear, terminations, or to learn from the experience of over 90,000 switchgear installations worldwide, visit www.nojapower.com.au or contact your local NOJA Power Distributor.

Quisiera recibir actualizaciones respecto a la tecnología para redes eléctricas de distribución?

Únase a nuestro boletín técnico semanal gratuito, en el cual compartimos nuestra experiencia en ingeniería eléctrica global directamente en su correo electrónico

Suscribirse →